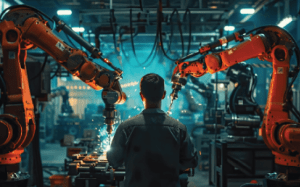

AI in Manufacturing: Redefining the Future of Production

The manufacturing industry is on the cusp of a major transformation, driven by the integration of Artificial Intelligence (AI). AI...

Manual tasks, resource bottlenecks, and outdated systems reduce productivity and increase downtime. Our AI-driven automation optimizes workflows and boosts overall operational performance.

Inconsistent quality checks and human errors impact product reliability. Smart quality control systems ensure precision, compliance, and reduced defects across every production stage.

Fluctuating demand and poor visibility cause production delays. AI-driven analytics improve forecasting, streamline logistics, and enhance supplier coordination.

PROBLEM

Traditional manufacturing processes often grapple with inefficiencies. These stem from manual tasks, production bottlenecks, and suboptimal resource allocation, which collectively hinder overall strategic objectives and competitive positioning.

PROBLEM

Maintaining superior and consistent product quality is paramount for market competitiveness and brand reputation. Leveraging AI-powered quality control systems strategically enables real-time defect detection, significantly reduces human error, and ensures stringent compliance with evolving industry standards. This proactive approach not only minimizes rework and waste but also safeguards customer satisfaction and long-term loyalty, thereby directly contributing to sustainable business growth and competitive advantage.

PROBLEM

Minimizing downtime and maximizing equipment uptime are critical strategic objectives for manufacturers. By leveraging AI-powered predictive maintenance, organizations can proactively anticipate and address potential equipment failures before they occur. This strategic approach significantly reduces costly disruptions, optimizes operational efficiency, and ensures maximum productivity, ultimately safeguarding profitability and enhancing overall competitive advantage.

PROBLEM

Effectively managing complex supply chains is a strategic imperative for competitive advantage and resilience. AI-driven analytics provide the real-time insights and proactive decision-making capabilities essential for optimizing inventory management, strengthening supplier relationships, and streamlining logistics operations. This strategic approach minimizes risks, reduces costs, and enhances responsiveness to market demands, ultimately securing a more robust and efficient end-to-end supply network.

The impact of industrial IoT on transforming manufacturing.

AI-powered predictive maintenance can reduce maintenance costs by up to 30% and decrease downtime by as much as 70%.

Reduce defects by 20% with AI-powered geometric accuracy and early fault detection.

Boost labor productivity and utilization by 25% by automating routine tasks and providing workers with faster, data-driven instructions.

Reduce waste by up to 25% with data-driven quality control, cutting expenses and enhancing sustainability.

A six-step roadmap to smarter, data-driven manufacturing.

To truly improve, you need to deeply understand your current standing. A Current State Analysis dives into your operations to identify critical inefficiencies, helping you pinpoint bottlenecks and waste. This clear view allows for precise, effective solutions.

Once you understand your current state, it’s time to define priorities. Pinpoint the high-impact areas where improvements will yield the most significant results, ensuring your efforts are focused for maximum benefit.

Technology Alignment means integrating solutions that truly fit your needs. Choose and implement tools that seamlessly enhance your processes, ensuring they work for you, not against you.

Continuously monitor and improve, staying agile in a competitive landscape.

A six-step roadmap to smarter, data-driven manufacturing.

To truly improve, you need to deeply understand your current standing. A Current State Analysis dives into your operations to identify critical inefficiencies, helping you pinpoint bottlenecks and waste. This clear view allows for precise, effective solutions.

Revolutionizing complex assembly lines with smart technologies, enabling faster turnaround and unparalleled precision.

Optimizing every stage of manufacturing, from raw materials to finished products, ensuring quality and consistency at scale.

The manufacturing industry is on the cusp of a major transformation, driven by the integration of Artificial Intelligence (AI). AI...

Predictive maintenance is a proactive maintenance strategy that uses data analysis and machine learning to predict when equipment failure might...

Introduction Manufacturers today operate in a highly competitive environment where product quality and reliability directly impact profitability and customer trust....

PUNE, INDIA – OCTOBER 16, 2025 – Tudip Digital, a leader in innovative software solutions, today announced the launch of VOXgent.AI, an AI-driven voice technology...

Read More

Like other industries, healthcare is also witnessing a surge in AI adoption. This adoption is driving a new set of opportunities in healthcare, enabling innovation...

Read More

29 November 2024 Tudip Technologies named a top B2B company for AI powered Digital Transformation services We are thrilled to announce that Tudip Technologies has...

Read More

Tudip Technologies proudly announces that its CEO, Dipti Agrawal, has been bestowed with the prestigious “Inspirational Woman Business Leader Special Award” on March 21, 2024.

Read More

Tudip Technologies, a distinguished CMMI Level 5 Company, leads the IT software and solutions landscape with a relentless commitment to excellence and cutting-edge AI technologies.

Read More

In an exclusive interview with Tech Achieve Media, Ms. Dipti Agrawal, CEO and Co-founder, Tudip Technologies, discusses the recent opening of Tudip’s Singapore office and its significance...

Read More

In an exclusive interaction with CIOL, Ms. Dipti Agrawal, our CEO and Co-founder, shares her vision on AI and the road ahead. AI is transforming...

Read More

The integration of Artificial Intelligence (AI) is no longer a distant future. In fact, it’s reshaping industries in real-time. Dipti Agrawal, Co-founder and CEO of Tudip Technologies, shares...

Read More

Tudip Technologies marked its 14th Foundation Day with unparalleled zeal and fervor as employees and stakeholders came together to witness & celebrate the journey of...

Read More

PUNE, INDIA – July 31, 2025 – Tudip Technologies is pleased to announce the successful conclusion of its exclusive Manufacturing 4.0 AI Summit, convened on...

Read More

Tudip Technologies, a global digital transformation organization, is hosting a significant manufacturing event on Wednesday, July 30, 2025, at the Hyatt Regency, Hinjewadi, Pune. The...

Read More

Tudip Technologies, a leader in innovative software solutions, today announced the launch of Testify.AI, its cutting-edge AI-powered testing platform. Designed to meet the demands of...

Read More

Tudip Technologies, a leading global provider of IT consulting, software development, and digital transformation services, today announced the launch of its newly revamped website, www.tudip.com.

Read More

Tudip Technologies proudly implemented Kuber at PCA Legal, enhancing employee welfare and productivity in their digital transformation journey.

Read More

See How Innovative Tools and Strategies are Redefining Education Watch the video and take the first step toward smarter learning today! Step Into the Future...

Read MorePromising to serve customers by both anticipating the future and reflecting on the past is a bold commitment, but the potential of today’s emerging digital capabilities is immense and rapidly expanding.

Let’s discuss how digital services and IT solutions for manufacturing can benefit your business.

Our clients turn to us to help them reimagine ways of working with technology.